Patented Name: Turbocharged Microcirculation Variable-Frequency Noise Reduction and Ventilation System

Patent No.: 200520108948.5

As the core solution for noise control in acoustic laboratories, this patented sound insulation system is based on the mass law in acoustic principles. It deeply integrates three key elements: material rigidity, damping characteristics, and structural coupling effects, to conduct refined and customized design of the laboratory's main structure, ensuring excellent noise isolation performance.

The mass law clearly states that the sound insulation performance of a material is positively correlated with its surface density and sound wave frequency. On this basis, the system further considers the blocking effect of material rigidity on sound wave propagation, improving the ability to resist sound wave penetration by optimizing the material's molecular structure. It converts sound wave vibration into heat energy to dissipate through the energy loss characteristics of damping materials, weakening the noise propagation energy. At the same time, it accurately regulates the coupling relationship between various structural components to avoid secondary noise caused by resonance between components, forming a triple noise reduction logic of "blocking-loss-vibration reduction".

The system shell adopts a multi-layer composite structure design, and the number of layers needs to be personalized according to the preset acoustic indicators of the laboratory (such as noise attenuation, cut-off frequency, etc.).

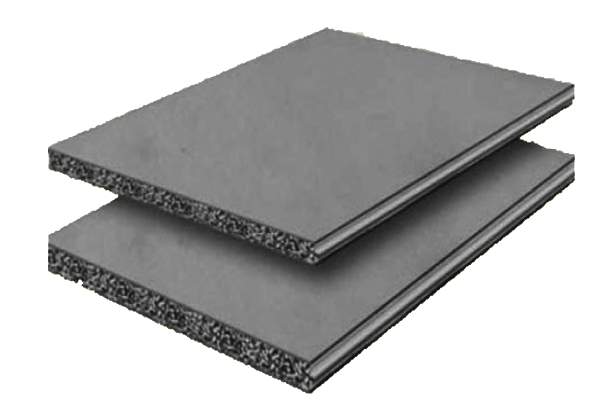

Composition of Composite Panels: Each layer of panel is a customized sound insulation and noise reduction composite material, integrating a high-density base material and a porous sound absorption layer. It can not only efficiently reflect sound waves but also absorb residual noise penetrating the surface layer.

Air Layer Design: An air layer is reserved between the panels, forming a "mass-elasticity" acoustic structure with the composite panels. The air layer can effectively block the solid conduction path of sound waves, and cooperate with the sound insulation effect of the panels to achieve precise treatment of noise in a wide frequency range.

Standard Dimensional Parameters: The thickness of the panels and the air layer is usually controlled within the range of 50-75mm. This size has been verified through a large number of acoustic simulations and experiments, enabling balanced and efficient isolation and attenuation of different frequency noises (including low-frequency vibration noise and high-frequency air-borne noise) in the range of 20Hz-20kHz.