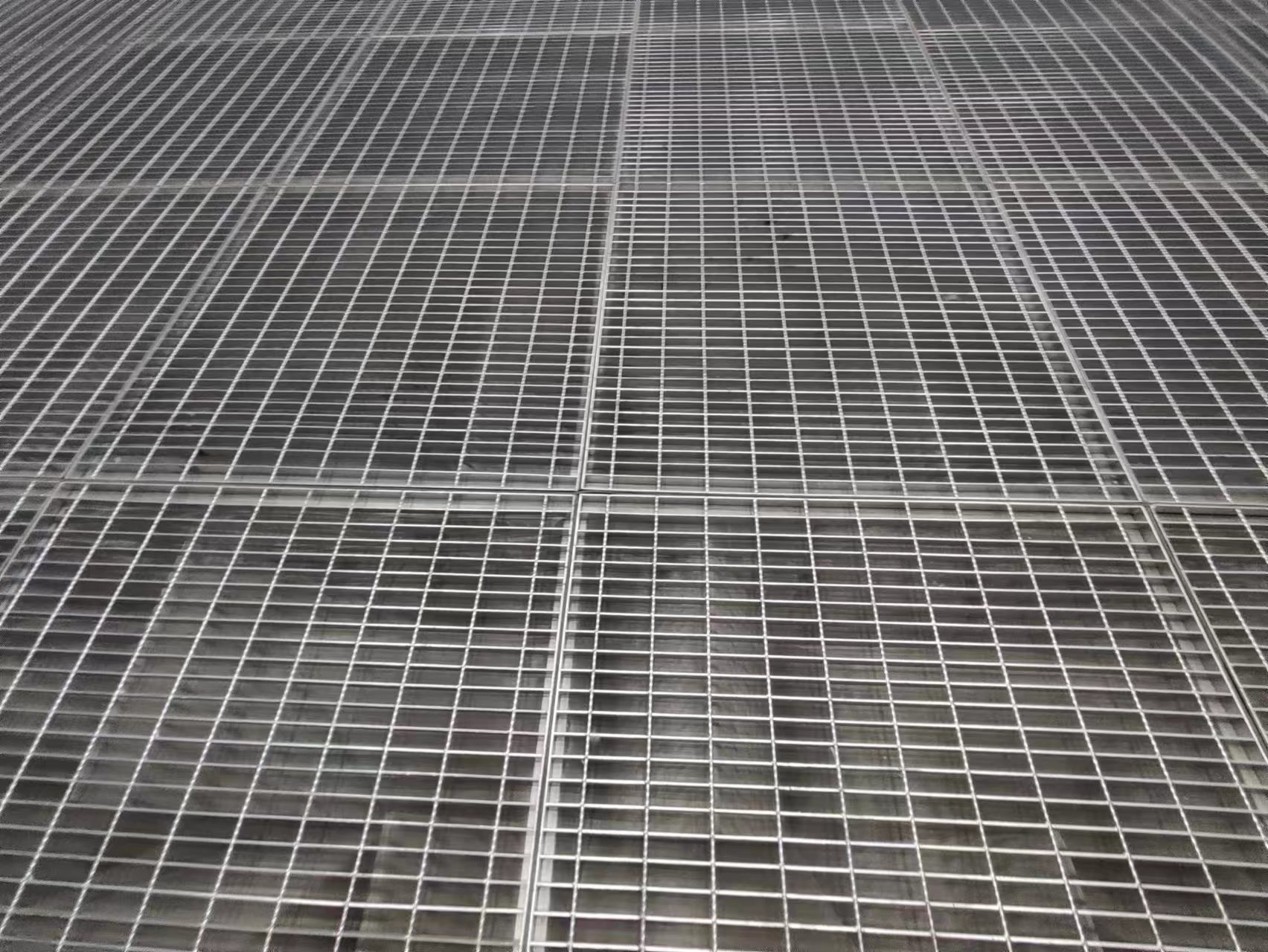

The ground grid structure inside a full anechoic chamber is mainly constructed with steel gratings, serving as a key component that ensures the integrity of the indoor acoustic environment and functional usability. It needs to not only adapt to the requirements of the acoustic system but also meet diverse needs in practical use. This structure is primarily composed of a steel grating main body and a supporting system: The load-bearing layer is centered on bearing flat steel and crossbars, arranged at reasonable intervals through orthogonal combination to form a stable load-bearing framework. It can safely support daily needs such as personnel passage, placement of test equipment, and sample positioning. The surface protection layer is made of thin metal plates; to balance practicality and adaptability, ventilation holes and maintenance holes are reserved on the plates. These holes not only ensure air circulation under the ground grid to prevent moisture accumulation from affecting the performance of acoustic materials but also provide convenient access for later equipment inspection, line arrangement, and maintenance operations.

The overall design of the ground grid structure balances structural stability and acoustic adaptability. Its permeable characteristics do not hinder the free propagation and efficient absorption of sound waves, forming a synergistic effect with the anechoic chamber’s sound absorption and vibration isolation systems to ensure stable indoor acoustic parameters.

Application Scenario Adaptation Instructions

Professional acoustic laboratories: For scenarios such as precision instrument testing and acoustic parameter calibration, the ground grid adopts denser steel grating arrangement. The positions and quantities of maintenance holes reserved in the protection layer are planned according to the laboratory’s equipment layout, and the load-bearing design is enhanced to meet the placement needs of large-scale test instruments.

Industrial noise reduction test cabins: For scenarios like industrial product noise detection, the ground grid optimizes the distribution of ventilation holes to improve air circulation efficiency, adapting to complex working conditions such as high temperature and high humidity inside the cabin. The metal plates of the protection layer are made of more wear-resistant and corrosion-resistant materials to extend service life.